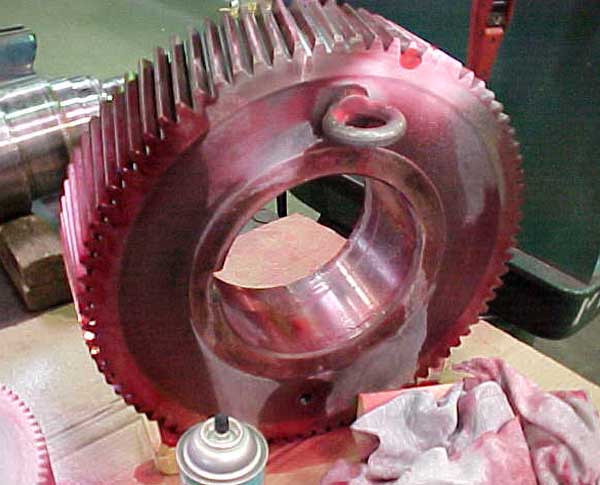

United Gear Works specializes in gear repairs onsite or in our facility. United Gear Works has lifting capacity to handle any size gear in our workplace. United Gear Works has the expertise to handle any Gear repair.

FIVE LOCATIONS IN THE USA

We Service and Repair wide range of industrial Gears.

At United Gear Works a warranty is offered for all gear repairs depending on the terms and conditions of the warranty. We want to give you the best possible repair, but also want to be assured that the gears we repair are properly maintained and periodically checked. Other warranty factors that must be considered are concerning history of the gear, metallurgy soundness, age of the particular gear to be repaired and fitness for purpose. United Gear Works works closely with companies that specialize in the proper maintaining of gears and companies that have the ability to re-cut the entire gear if necessary. In the most extreme cases it may be necessary to re-cut the entire gear.

The repair aspect can consist of repairing cracked and/or broken teeth, United Gear Works has the machining capability to machine these teeth back in place when the weld repair is complete. This is portable and can all be done onsite to minimize downtime and costly rigging charges.

United Gear Works has a full time weld engineer on board to determine the best procedure for your gear repair with certified welders to see thru the repair. United Gear Works also offers certified NDE level III as well to locate defects, make sure defects are fully removed and a sound repair is reassured with final inspection.

We rebuilt gears to meet original manufacturer's specifications

United Gear Works Has Over 55 Years In The Gear Repair Industry We Can Provide Custom Manufacturing Of Gears Up To 25’ diameters Or 30,000 lbs! Where Our Competitors Would Simply Offer A 12 Month warranty We Go The Extra Mile And Offer A 48 Month Warranty On All Repairs No Matter How Big Or Small

We Have Been Around For A While Now So We Have a Lot Of Experience Of Repairing Gears! And We Will Earn Your Trust Through Our Extensive Customer Support And Repair Capabilities We Will Not Let You Down!

United Gear Works creates a detailed report listing all possible solutions, including the preferred method of repair necessary to return the gearbox to premium working condition. The optimal approach could involve replacing loose gears in damaged gear sets or the entire set, along with splines, shafts and bearings.

List of Gears that we work and many others foreign or domestic

Ball Mill Gears And Pinions Repair

Bevel Gears Repair

Brass And Worm Gears Repair

Bull Gears Repair

Chains Gears Repair

Crossed Helical Gears Repair

Crusher Mill Gears & Pinions Repair

Double Enveloping Worm Gears Repair

Double Helical Gears Repair

Dryer Gears Repair

Face Gears Repair

Gear Rack Repair

Gears for Dragline Repair

Gilmer Timing Gears Repair

Ground and Carborize Gears Repair

Hammer Mill Gears & Pinions Repair

Helical Gear Rack Repair

Helical Gears Repair

Herringbone Gears Repair

HTD Power Grip Gears Repair

Hypoid Gears Repair

In-Line Helical Gears Repair

Internal Gears Repair

Internal Ring Gears Repair

Involute Splines Gears Repair

Kelm Gears Repair

King Gears Repair

Miter Gears Repair

Pinion Gears Repair

Planetary Gears Repair

Racks Gears Repair

Raymond Mill Gears & Pinions Repair

Ring Gears Repair

Roller Chain Gears Repair

Rotary Kiln Gears & Pinions Repair

S-Type Gear Repair

SAE Splines Gears Repair

Sag Mill Gears & Pinions Repair

Silent Chain Sprockets And Gears Repair

Speed Increaser Gears Repair

Speed Reducer Gears Repair

Spiral Bevels Gears Repair

Spline Gears Repair

Split Herringbone Gear Repair

Sprockets Gears Repair

Spur Gears Repair

Straight Bevel Gears Repair

Tangential Worm Cutting Gears Repair

Time Gear Sets Dragline/Shovels Repair

Vertical Gear Pump Repair

Worm Gears Repair

Ball Mill Gears And Pinions Repair

Bevel Gears Repair

Brass And Worm Gears Repair

Bull Gears Repair

Chains Gears Repair

Crossed Helical Gears Repair

Crusher Mill Gears & Pinions Repair

Double Enveloping Worm Gears Repair

Double Helical Gears Repair

Dryer Gears Repair

Face Gears Repair

Gear Rack Repair

Gears for Dragline Repair

Gilmer Timing Gears Repair

Ground and Carborize Gears Repair

Hammer Mill Gears & Pinions Repair

Helical Gear Rack Repair

Bevel Gears Repair

Brass And Worm Gears Repair

Bull Gears Repair

Chains Gears Repair

Crossed Helical Gears Repair

Crusher Mill Gears & Pinions Repair

Double Enveloping Worm Gears Repair

Double Helical Gears Repair

Dryer Gears Repair

Face Gears Repair

Gear Rack Repair

Gears for Dragline Repair

Gilmer Timing Gears Repair

Ground and Carborize Gears Repair

Hammer Mill Gears & Pinions Repair

Helical Gear Rack Repair

Helical Gears Repair

Herringbone Gears Repair

HTD Power Grip Gears Repair

Hypoid Gears Repair

In-Line Helical Gears Repair

Internal Gears Repair

Internal Ring Gears Repair

Involute Splines Gears Repair

Kelm Gears Repair

King Gears Repair

Miter Gears Repair

Pinion Gears Repair

Planetary Gears Repair

Racks Gears Repair

Raymond Mill Gears & Pinions Repair

Ring Gears Repair

Roller Chain Gears Repair

Herringbone Gears Repair

HTD Power Grip Gears Repair

Hypoid Gears Repair

In-Line Helical Gears Repair

Internal Gears Repair

Internal Ring Gears Repair

Involute Splines Gears Repair

Kelm Gears Repair

King Gears Repair

Miter Gears Repair

Pinion Gears Repair

Planetary Gears Repair

Racks Gears Repair

Raymond Mill Gears & Pinions Repair

Ring Gears Repair

Roller Chain Gears Repair

Rotary Kiln Gears & Pinions Repair

S-Type Gear Repair

SAE Splines Gears Repair

Sag Mill Gears & Pinions Repair

Silent Chain Sprockets And Gears Repair

Speed Increaser Gears Repair

Speed Reducer Gears Repair

Spiral Bevels Gears Repair

Spline Gears Repair

Split Herringbone Gear Repair

Sprockets Gears Repair

Spur Gears Repair

Straight Bevel Gears Repair

Tangential Worm Cutting Gears Repair

Time Gear Sets Dragline/Shovels Repair

Vertical Gear Pump Repair

Worm Gears Repair

S-Type Gear Repair

SAE Splines Gears Repair

Sag Mill Gears & Pinions Repair

Silent Chain Sprockets And Gears Repair

Speed Increaser Gears Repair

Speed Reducer Gears Repair

Spiral Bevels Gears Repair

Spline Gears Repair

Split Herringbone Gear Repair

Sprockets Gears Repair

Spur Gears Repair

Straight Bevel Gears Repair

Tangential Worm Cutting Gears Repair

Time Gear Sets Dragline/Shovels Repair

Vertical Gear Pump Repair

Worm Gears Repair

We Also Repair All Other Makes And Models Of Gears

At our Gear Repair Facility